iTEch Control Unit

The Transmon iTEch Control is a singular unit that combines multiple functions all from the same unit. These include Road Speed Control, Tyre Wear Reduction, Engine Idle Shutdown and Auto Shift Control.

The unit offers our customers reduced truck damage, with savings on fleet maintenance and an increased resale value, as well as improved site safety due to speed limit enforcement.

Transmon offers two different iTEch controllers for Limiting Drive Speeds:

– RSPC1 for ICE powered forklift and mobile plant equipped with mechanical-cable accelerator pedals.

– iTEch7 for ICE and Electric powered forklift and mobile plant equipped with Drive-by-Wire accelerator pedals.

iTEch7 supports 3 different speeds, RSPC1 supports 2 different speeds.

How it works

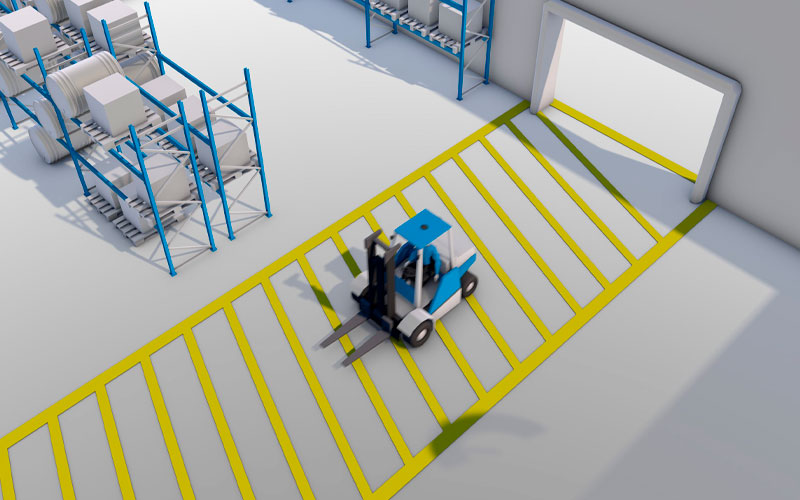

The iTEch 7 is designed specifically for forklift trucks. The system monitors actual road speed and applies engine throttle restriction as required to obtain the correct speed. The engine speed limit is removed as the truck slows to allow full power to the hydraulics. We can apply up to three different speeds to be used in many different ways:

- Above set load – activate second speed

- Above set height – activate second speed

- Automatic zone change with the higher speed driver selection

- Manual select with reverse

- Manual select switched with beacon warning at high speed

Optional Solutions:

Tyre Wear Reduction

The system helps to reduce tyre wear by preventing ‘drive’ unless the road speed and engine revs are below a pre-set limit. This can be coupled with an inching-pedal switch which helps to protect the clutch pack in the same way.

Engine Idle Shutdown

We are also able to shutdown the forklift truck engine when not being used and the timing is adjusted to suit your individual needs. (1-1200 seconds). This helps to reduce idle time wear, fuel/battery usage and reduces service hours which in turn reduces over-servicing.

Auto Shift Control

On two speed vehicles, this application will automatically change gear at certain speeds to ensure the truck is always in the right gear. This helps our customers to reduce engine wear across their fleet through over-revving. The system also increases operator control of the vehicle.

Benefits

- Extremely cost effective way of reducing maintenance costs and improving safety

- Takes up little space so ideal for almost any kind of truck

- Plug and play wiring loom adapters

- Compatible with both drive by wire throttle systems and cable throttle pedals

- Speed not affected by inclines

- Lifting not affected

- Designed and built in the UK

Need more info?

Contact Us

For further assistance or to request a quote, please fill out the form below.

Read the case study for Etrak

Transmon’s Speed Safety Zone solution was to install its low frequency zoning system to the ramp side rails at the top and bottom of the entry and egress to the ramp. This would allow the tug trucks using the ramp to maintain a slow speed coming down the ramp when towing goods, to ensure the truck left the bottom of the ramp at a safe speed, preventing spillage and any potential damage to the customer’s engine parts.