Adaptive Speed Control For Safer Warehouses

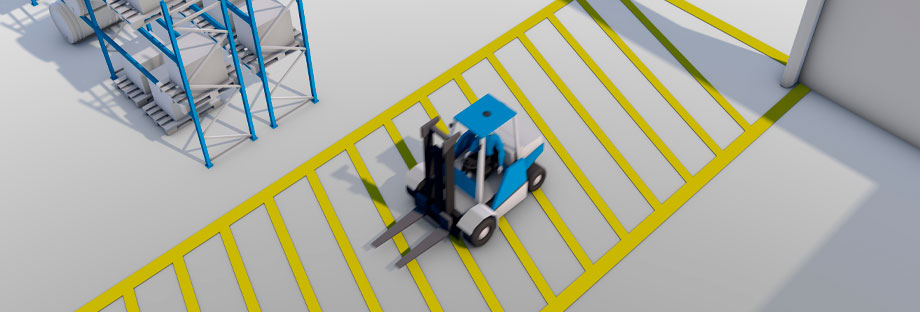

Driver aids such as pedestrian warning systems are frequently used at warehouse, production and manufacturing sites across the country. Wherever you have material handling equipment and people interacting, there is always a real risk of a collision.

With confined spaces in warehouses with narrow aisles full of stock, pick and pack areas as well as product arriving via goods in and out via dispatch, there are numerous pinch points where accidents can happen.

However, where pedestrian warning systems solely use alarms or flashing lights to identify a potential obstruction, you are relying on the driver to react quickly to avoid any collision. In practical terms we can allow a 1.5-2.0 second reaction time for a typical driver. The alarm sounds when a pedestrian is detected but if travelling at 10mph (16.1kmh) a driver could have covered 22-29ft (6.7-8.9m) in this time and perhaps need as much as 32ft (9.7m) to come to a complete and safe stop.

By integrating an Adaptive Speed Control system with a forklift or other material handling equipment, the Speed Controller assists the driver by reacting immediately upon sensing a pedestrian or other obstacle in the vicinity, the driver’s reaction time to slow the truck is avoided, and the truck starts to brake automatically.

Enforcing a site speed limit is an excellent way to improve site safety, however Dynamic Speed Management can take site safety to an even higher level. Radar, RFID, UWB, LiDAR and Ultrasonic technologies are readily available and often used in combination with Adaptive Speed Control systems to provide Dynamic Speed Management. Truck speeds will be dynamically managed in accordance with the changing working environments or level hazard.

One such recent integration for us, took place at a food production facility where forklift trucks were automatically slowed when entering a controlled ‘speed zone’ so that they could safely, yet efficiently, travel within the area yet not compromise personnel safety of those working in the central packing area.

Now more than ever when warehouse space is at a premium, and increased volume of stock and number of workers share the same space, it’s a combination that can and will lead to situations where machines and people come too close for comfort. Using Adaptive Speed Control solutions will enhance operations and improve safety across the board.